Choosing the Right Product Form: Precision Strip, Flat Wire, or Shaped Wire

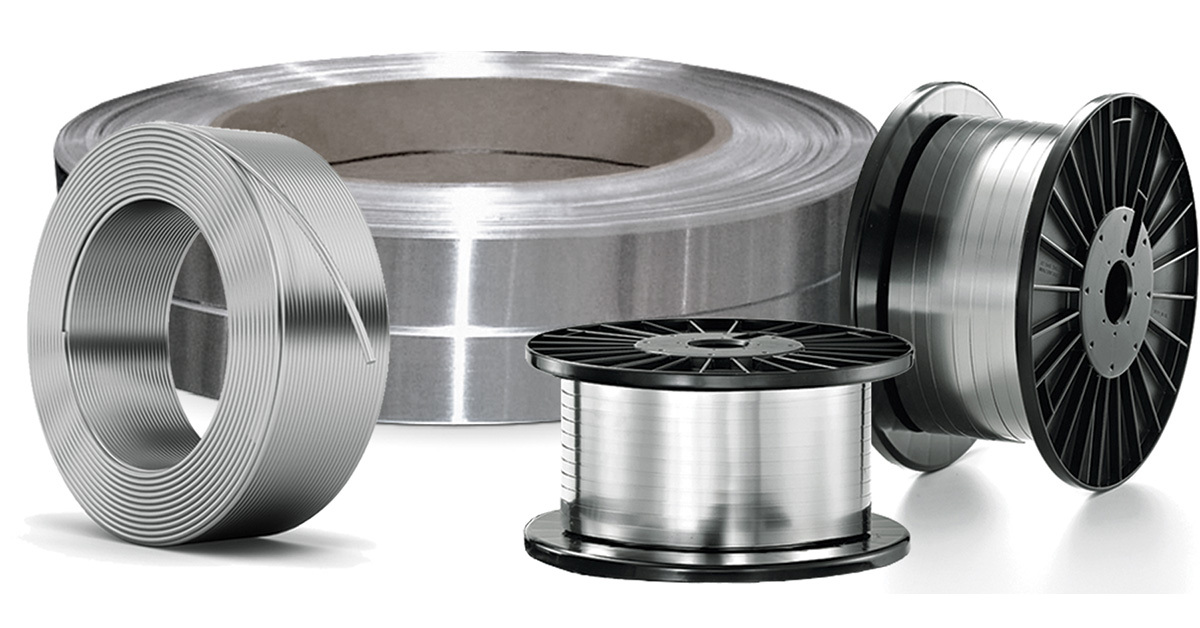

When designing precision metal components, many manufacturers automatically default to precision strip because it’s familiar, widely available, and effective for countless stamping and forming applications. But in some cases, flat wire or shaped wire may deliver a better result.

These alternate forms can improve coil efficiency, enhance edge quality, and even eliminate secondary machining operations. They also open new design possibilities for engineers working with parts that require tight tolerances, asymmetric edges, or unique cross-sections.

At Ulbrich, we understand that every process is different. Our ability to roll both narrow and wide-width precision strip, combined with our flat and shaped wire capabilities, gives customers flexibility to select the best product form for their application.

This article explores how we help customers decide when precision strip is the right choice, when to transition to flat wire, and when shaped wire offers the greatest performance and efficiency advantages.

When Precision Strip is the Right Choice

Precision strip remains the foundation for many formed and stamped parts. It’s efficient, consistent, and ideal when lighter gauge, wider-width material and symmetrical edges meet your needs.

Standard Stamping Applications

If your part geometry is relatively simple and uses conventional press tooling, precision strip is almost always a more cost-effective option. It’s available in a wide range of alloys and tempers, and Ulbrich’s re-rolled strip achieves the flatness, finish, and tolerance control that precision stampers depend on.

Wide Widths and Coil Handling

Strip can be slit and rewound efficiently at widths of half an inch and above, maintaining good coil stability and manageable handling characteristics. When parts require wide blanks or multiple features formed per stroke, strip maximizes productivity and minimizes setup time.

Symmetrical Edges and Flat Profiles

For components where edge contour doesn’t affect function, precision strip offers excellent consistency. When paired with Ulbrich’s controlled annealing and rolling process, strip maintains tight gauge control, fine grain size, and uniform mechanical properties across the coil.

In short, precision strip is the right choice when your process relies on flat, symmetrical material that feeds efficiently through standard stamping or forming equipment.

When to Transition from Strip to Flat Wire

When applications start to approach the dimensional or edge limitations of precision strip, flat wire can provide distinct benefits. Precision strip remains the preferred option for most applications, but flat wire becomes practical when slitting or edging reaches its physical limits, or when larger coil sizes and enhanced edge control improve production efficiency.

Narrow Width Advantage

Flat wire can be rolled significantly narrower than precision strip, particularly at thicker gauges.

As a general guideline, anything above about 0.050" thick typically has a minimum slit width around 0.5". Below that, strip is often still the best option, though it can eventually reach a point where slitting is no longer feasible. When the required width becomes too narrow for slitting or strip edging, flat wire allows those dimensions to be achieved with clean, consistent edges.

Coil Size and Production Efficiency

When strip is slit to narrow widths, the result is often small coils that require frequent press changeovers. Flat wire can achieve the same narrow dimensions in larger coil sizes, minimizing downtime and improving productivity.

Edge Quality and Flexibility

Because of how flat wire is processed, it naturally achieves a cleaner, smoother radius edge. Slit strip edges are more angular, created through a skiving or shearing process that approximates a rounded shape. When applications demand a true radius, beveled, or asymmetrical edge, flat wire or shaped wire provides the precision needed for optimal performance.

Symmetrical vs. Asymmetrical Edges

Precision strip is limited to symmetrical edges on both sides. Flat wire and shaped wire can be engineered with differentiated edges, such as one side square and the other beveled. This allows designers to eliminate additional machining or edge-conditioning operations.

Why and When to Choose Shaped Wire

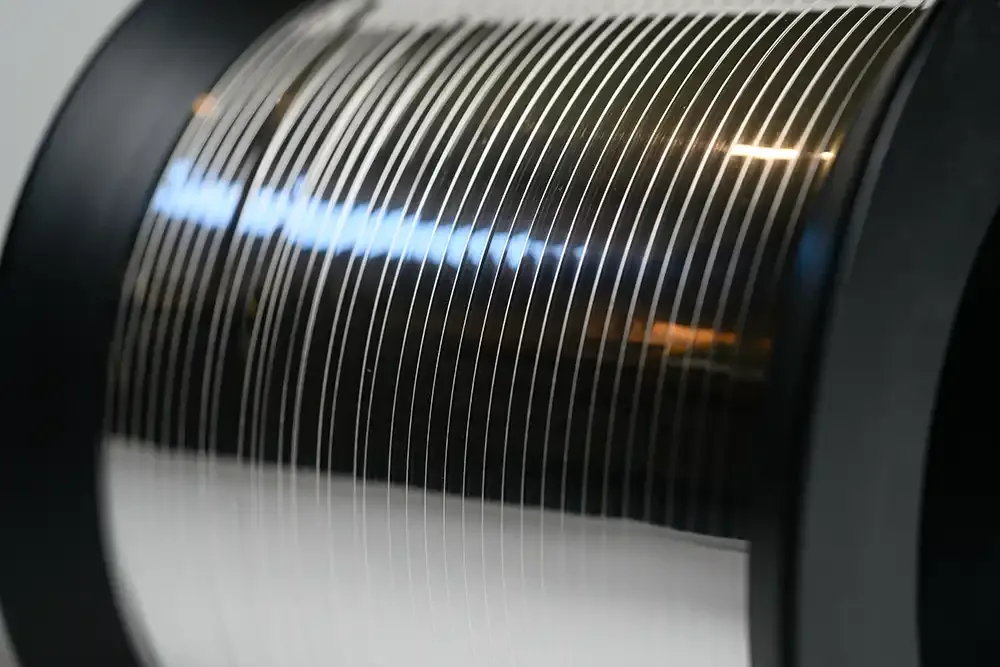

While flat wire provides improved edge control and coil efficiency, shaped wire goes further by enabling complex geometries and precise profiles that remove multiple downstream processes.

Eliminating Secondary Machining

Shaped wire can incorporate the contour and form directly into the material. Instead of starting with flat stock and stamping or coining it into shape, engineers can specify a cross-section that arrives ready for the next stage of production. This saves time, reduces tooling wear, and minimizes handling.

Engineering Complex Features

Certain geometries such as step-downs, tapers, or dual-gauge transitions are difficult to form consistently using traditional stamping. Shaped wire makes it possible to build these features into the starting material, ensuring consistency from coil to coil.

Improving Consistency and Reducing Stress

Because the shape is formed during the rolling and drawing process rather than through heavy pressing, dimensional consistency improves and residual stresses are minimized. This helps reduce distortion during forming and maintains stable mechanical properties throughout the part.

Optimizing for Existing Equipment

Not every manufacturer has access to large high-tonnage presses. Shaped wire allows smaller equipment to produce high-precision parts by removing the need for deep forming or coining. It transfers complexity from the pressroom to the material supplier, allowing engineers to focus on assembly and performance rather than metal shaping.

Reducing Scrap and Cold Work

By starting closer to the finished geometry, less material is displaced or removed. This improves material yield and reduces cold work in sensitive or fatigue-prone areas, extending part life in demanding applications.

A Hybrid Approach: Combining Strip and Wire Capabilities

Because Ulbrich operates both precision strip mills and a shaped wire facility, customers can benefit from a hybrid approach that leverages the strengths of each.

In some cases, precision strip produced at Ulbrich’s Specialty Strip Mill can be further processed at Ulbrich Specialty Wire Products to create engineered edges that go beyond the dimensional limits of traditional wire rolling. This integrated process offers:

- Wider engineered profiles than typical wire products

- Consistent metallurgical quality from start to finish

- Access to both rolling and shaping expertise to ensure material that performs as designed

This dual capability allows Ulbrich to provide solutions that competitors limited to one form simply cannot.

Real-World Applications

Here are a few situations where choosing flat wire or shaped wire proved advantageous to a strip or slit coil product.

Medical Example

A medical device manufacturer needed a custom profile for a surgical component but lacked the press capacity to form it from flat strip. By sourcing shaped wire, the team achieved the same geometry using existing equipment, avoiding major capital investment and reducing forming strain on the part.

Industrial Example

An industrial customer required a step-down, dual-gauge profile that standard stamping couldn’t produce consistently. Ulbrich supplied shaped wire with the profile built in, eliminating a secondary forming step and improving uniformity across thousands of parts.

Design Example

In another case, a design engineer realized that a feature once thought unmanufacturable could, in fact, be produced through Ulbrich’s shaped wire process, simplifying assembly and improving functional performance.

Key Takeaways

- Choose Precision Strip when:

- You need light-gauge, wide-width material, symmetrical edges, or standard coil processing.

- Your application falls within typical slitting ranges, generally 0.5" wide or greater at standard gauges.

- You’re prioritizing cost efficiency and compatibility with established stamping or forming tools.

- Choose Flat Wire when:

- You require very narrow widths, typically below about 0.5" and in some cases as narrow as 0.040", depending on gauge.

- You want longer coil lengths (at narrow widths), fewer changeovers, or smoother radius edges for improved formability.

- You need to minimize burrs or achieve specific edge profiles that standard slit strip can’t deliver.

- Choose Shaped Wire when:

- Your design calls for engineered edges, asymmetric shapes, or multi-gauge profiles that replace secondary machining steps.

- You’re seeking improved consistency, reduced cold work, and optimized performance without large-press forming.

- Combine Both when:

- You want to take advantage of Ulbrich’s integrated strip and wire production, rolling precision strip and shaping edges like wire for maximum flexibility and consistency.

Choose the Ideal Product Form for Your Needs

Selecting the right precision metal starts with choosing the proper width and gauge. But savvy manufacturers can work smarter by engineering efficiencies through optimal material and form selection.

Whether you need precision strip, flat wire, or shaped wire, Ulbrich can help identify the option that delivers the best combination of performance, consistency, and cost savings for your application.