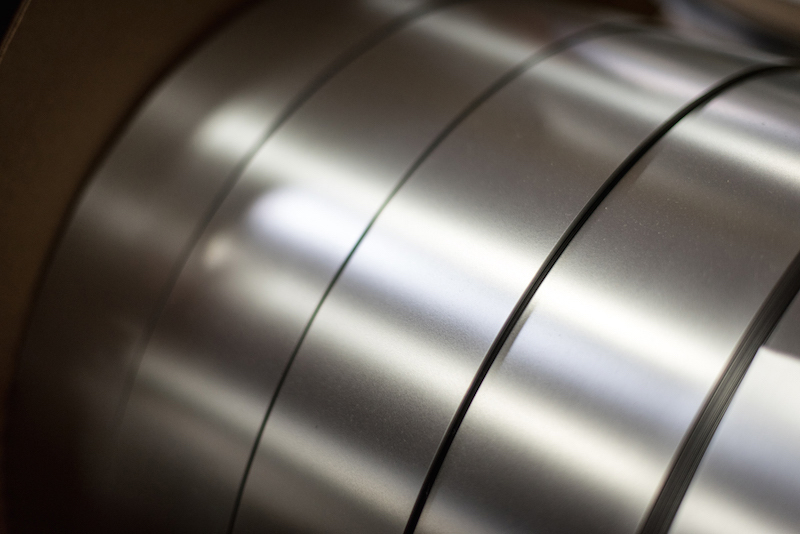

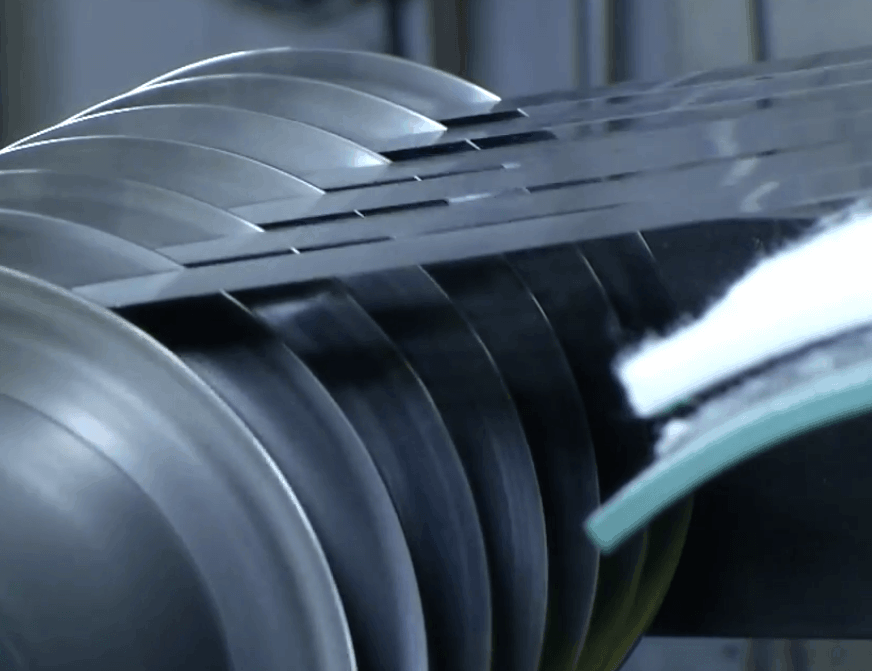

Strip Coil

At Ulbrich, we understand that precision is everything. That’s why we’ve expanded our capabilities to deliver custom precision-rolled strip up to 48" wide, paired with industry-leading tight tolerances, custom mechanical properties, and bespoke finishes. With decades of metallurgical expertise, we partner with you to ensure your materials perform seamlessly in your production process—and in the final product.