Special Metal Spotlight: Tantalum

If you were to pick one word to appropriately describe tantalum "versatile" would certainly be among those at the top of the list.

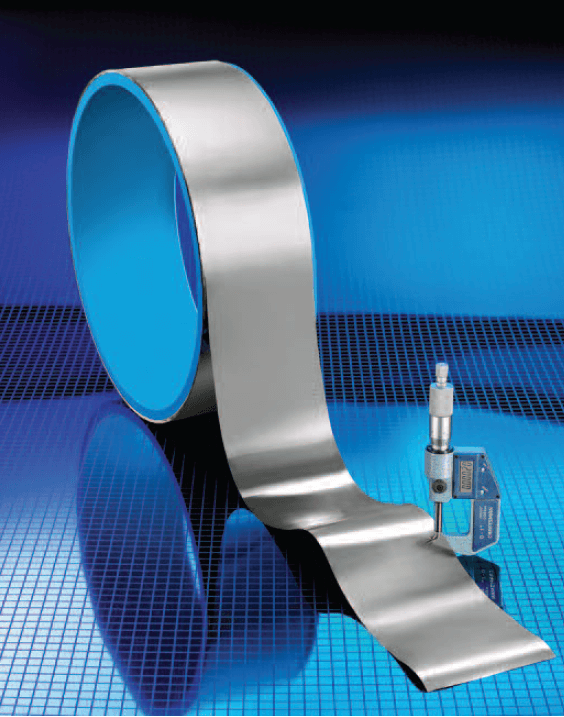

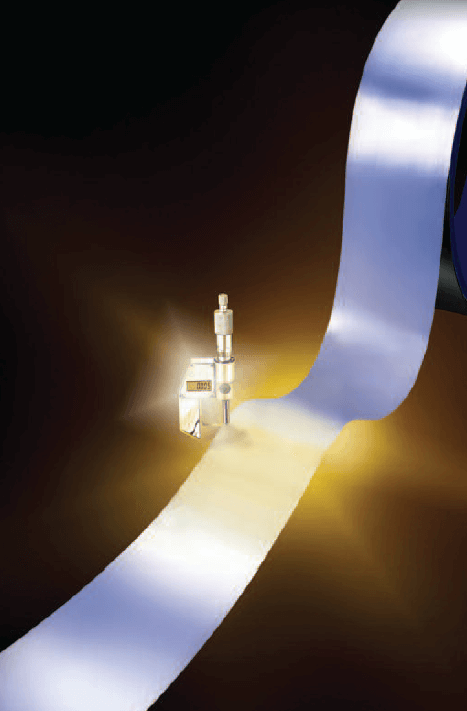

Tantalum — a shiny, silver metal named after the Greek God Tantalus — has myriad uses in modern industries ranging from high-temperature applications such as aircraft engine parts to electrical devices and medical applications. It has long been used in the manufacture of capacitors, but more recently it also has been found to be a desirable element in shaped wire applications.

In addition, its extraordinary corrosion resistance makes it uniquely attractive for medical implants ensuring reliability in devices that can enhance human life. Tantalum's corrosion-resistant properties also make it ideal for use in acid-rich environments. Interestingly, the metal is rarely found in its pure form but rather is mined in combination with other metals including tantalite, manganese, niobium, samarskite, and pyrochlore. Most of the world's supply of tantalum comes from Brazil, central Africa, Southeast Asia, Australia, Canada, and China.

Characteristics of Tantalum

| Atomic Number: | 73 |

| Atomic Mass: | 180.95 g.mol -1 |

| Melting Point: | 2850 °C |

| Boiling Point: | 6000 °C |

| Element Classification: | Transition Metal |

| Appearance: | Shiny, Silvery |

Tantalum has emerged as a preferred metal for electronics uses because it can withstand very high heat in a vacuum. This property, coupled with its relatively low cost, has made it an excellent replacement for platinum in electronic devices. Electronics manufacturers have been able to significantly reduce the size and cost of numerous electronic devices such as cell phones while simultaneously increasing their range of functions, partly through the use of compacted tantalum powder in capacitors.

Tantalum capacitors are used in medical devices such as hearing aids and pacemakers. The metal is used in capacitors in automobile computer circuitry to regulate not only basic functions such as engine control and airbag deployments but is also currently found in anti-lock braking systems and global positioning systems.

Other electronics with tantalum capacitors include digital and video cameras, video games, and laptop computers. The metal’s capacitors are preferred in many electronic uses because they are more efficient than capacitors made from other materials; have excellent power dissipation characteristics; are highly reliable, and have an unlimited shelf life.

Thus tantalum powder is highly sought after and can cost as much as $76 per gram. It should be noted, however, that there are a few cautions regarding tantalum powder and how it is produced and handled. The phrase ‘give him a little breathing room’ may be good advice for someone who needs to think things over, but it is the worst possible scenario for tantalum powder, which really gets hot under the collar in an oxygen-rich environment.

In a vacuum, you can work wonders with tantalum, but like Tantalus, it can be volatile in the wrong situation and spontaneously ignite. This can take the form of an explosion in a confined environment. Proper handling precautions thus are absolutely necessary where tantalum powder is produced and applied.

Nonetheless, there are many other forms of tantalum in use in modern industry, and if handled properly, it has myriad applications and is entirely safe. These forms include tantalum carbide, tantalum oxide, and tantalum sheets, plates, rods, and wires. Tantalum carbide is used in cutting tools. You may, for example, read articles and e-mails printed from your computer on paper with the use of an ink-jet printer. Moreover, tantalum oxide is used in camera lenses and even X-ray film.

In short, it is a go-to metal with an incredible range of applications in an equally wide range of forms. The development of tantalum applications is keeping pace with advancing technology and its development should continue as technology progresses.

By John Schmidt