How to Choose the Right Material for Your Bellows Application

Whether your application is in aerospace, semiconductor, automotive, or medical, choosing the right metal directly impacts your bellows’ durability, flexibility, and overall performance.

So, what should you look for in bellows material? From weldability to corrosion, fatigue, and high-temperature resistance, critical material properties must be considered, and not all metals perform equally under pressure.

In this blog, we’ll walk through the most important factors to consider when selecting a metal for your bellows, compare material options for different manufacturing methods, and share how Ulbrich helps manufacturers source precision strip coil engineered for success.

Want a deeper dive into the alloys, manufacturing processes, and material specs critical to bellows manufacturing?

Download Our Full Bellows Whitepaper

Bellows Applications in High-Stakes Industries

Bellows are found in critical systems where precision and performance matter. Common applications include:

- Semiconductor: Vacuum chambers requiring tight motion control

- Medical: Devices like ventilators and surgical robots

- Automotive: Exhaust systems managing thermal expansion

- Industrial: Piping systems absorbing vibration and movement

- Aerospace: Fuel and water systems under extreme conditions

- Petrochemical: Cryogenic and high-temp processing environments

Each of these markets presents unique demands, so material selection must align with the application.

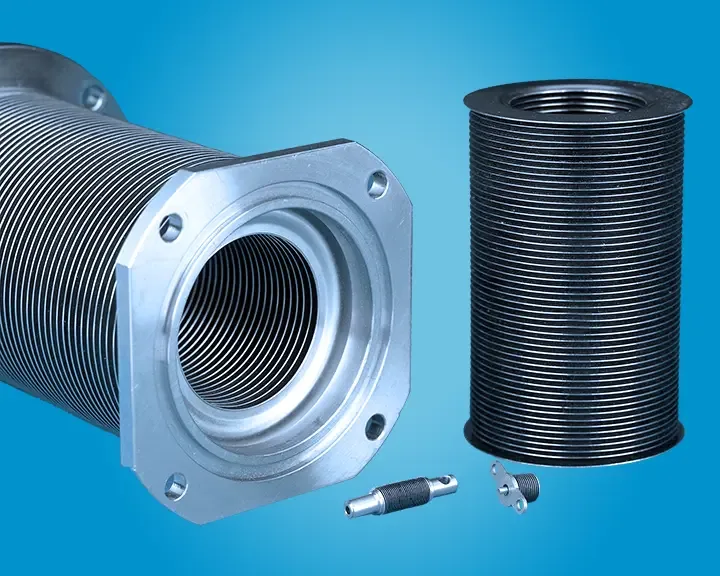

Formed vs. Welded Bellows: Why It Matters

Not all bellows are manufactured the same way, and the selected process influences which materials will perform best.

Welded Bellows

- Made by laser- or TIG-welding thin metal diaphragms

- Used in high-precision, smaller-scale applications

- Common alloys: AM350, Inconel 625, Titanium

Hydroformed Bellows

- Formed by expanding a welded tube using high-pressure fluid

- Suitable for larger, more durable components

- Common alloys: 304, 316, 321 stainless steels

Each method demands metals with specific properties — from weldability to ductility and strength under stress.

6 Material Properties That Define Performance

These six critical characteristics play an outsized role in long-term bellows performance:

- Weldability

Essential for diaphragm joining and seam welding. Alloys like AM350 and Inconel 625 perform well post-weld. - Fatigue Resistance (LCF)

Especially important in high-flex environments like aerospace or semiconductor systems. - Corrosion Resistance

Key for longevity in chemical processing, medical implants, or outdoor environments. - High-Temperature Stability

Required for exhaust systems or jet engine components operating under heat. - Formability & Ductility

Necessary for hydroformed bellows—materials must stretch without cracking. - Grain Size & Surface Finish

Finer grains support fatigue life and strength. Smooth edges improve weld quality and reduce stress points.

Ulbrich’s Role in Bellows Success

At Ulbrich, we do more than supply strip coil, we help engineers and manufacturers solve performance problems through smarter material sourcing.

- Metallurgical Support: Recommendations for alternative alloys, failure analysis, and certification assistance

- Precision Slitting & Edging: Uniform burrs and edges for seamless welding and forming

- Tight Tolerances: Consistent gauge and width control, from the lightest gauges to the widest-width strip

- Inventory Access: Readily stocked materials to support shorter lead times and greater flexibility

Whether you’re designing a diaphragm for a surgical robot or forming exhaust bellows for an EV, Ulbrich can supply the material that meets both your performance needs and your production realities.

Need Help Choosing the Right Metal?

Download the full whitepaper to learn:

- How different alloys compare in fatigue, corrosion, and heat resistance

- Why certain metals are better for welded vs. hydroformed bellows

Get Ulbrich’s Complete Guide to Sourcing Precision Metals for Bellows Manufacturing