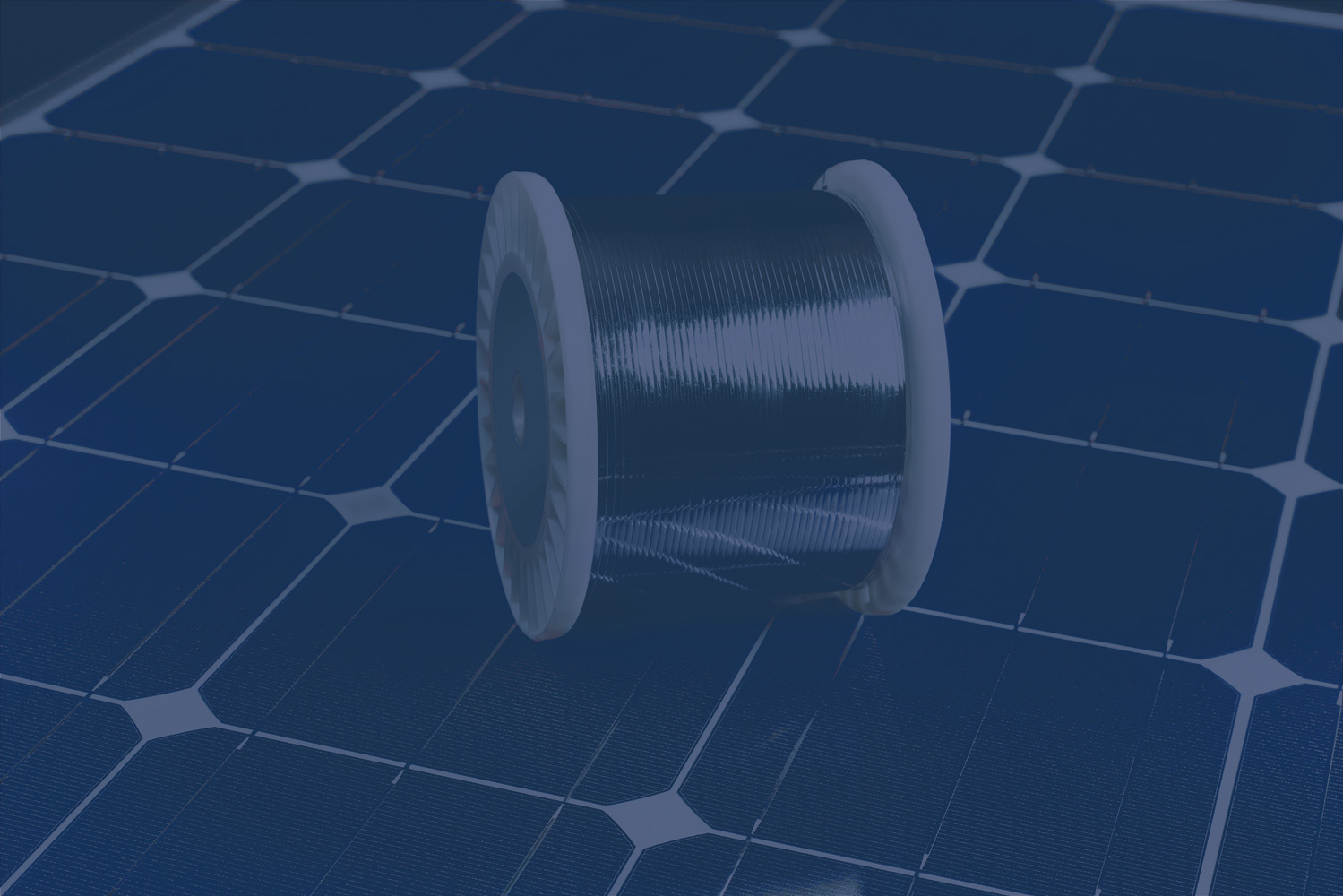

Ulbrich Specialty Wire Products is a world leader in PV Ribbon products. Years ago, we developed Multi-Tabbing PV Wire, a solder coated round wire for high efficiency solar cell modules.

Innovative solar cell concepts require adaptive bus bar technologies that promise efficiency gains, lower series resistance, less shadowing and the reduction of silver consumption.

Two and three bus bar technologies have dominated the solar industry, but advanced and more powerful generations of solar cells require new designs and a higher number of bus bars to carry the extra current. Today’s technology includes up to six or more bus bars.

Multi-Tabbing PV Wire’s small dimension of round wire allows a narrower bus bar width on the solar cell, reducing the shadowing loss with traditional rectangular ribbon, while maintaining optimal power gains for the best output results.

Multi-Tabbing PV Wire offers the same high quality and performance standards you would expect from other Ulbrich products supplied to the PV industry.

Ulbrich Solar Technologies Inc. (UST), is a world leader in PV Ribbon products used to interconnect and transmit current for crystalline silicon and thin film solar cells. For decades, UST has supplied the solar industry with tinned flat copper ribbon while continuously identifying emerging PV Ribbon technologies and engineering innovative solutions to increase the electrical output and performance of solar modules.