What’s Really Behind the Wait? A Manufacturer’s Guide to Coil Lead Times

A reliable supply of coil is the difference between a smooth production run and a costly disruption. Missed shipments, unplanned downtime, and late deliveries can wreak havoc on your operations and relationships.

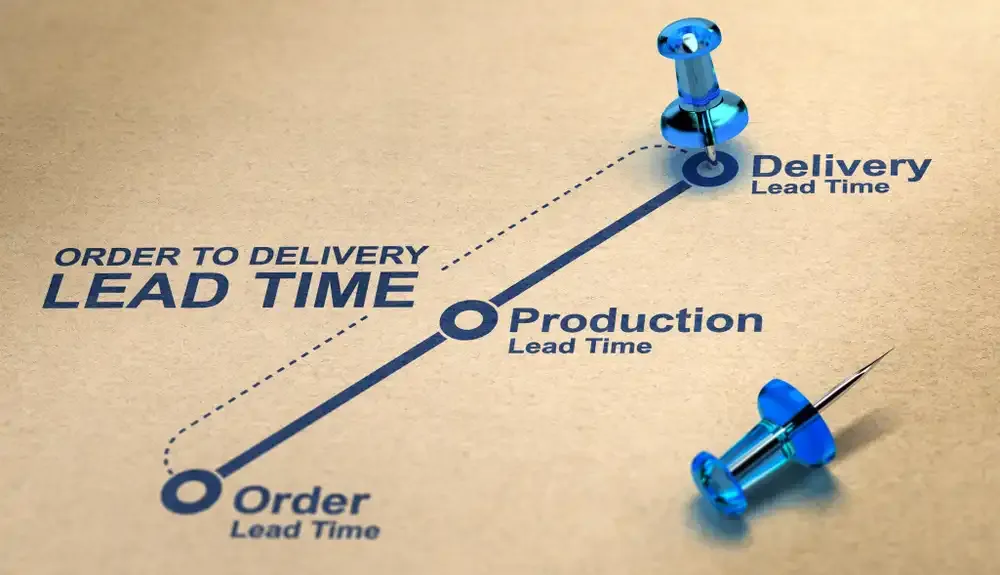

But here’s the frustrating part: lead times aren’t always easy to predict. One order takes four weeks. Another takes twelve. Why?

Let’s break down the sources of lead time variability, from the furnace to your facility. By understanding the upstream reality, you can make better decisions, avoid delays, and keep production humming.

It All Starts at the Melt Mill

The Invisible Clock Behind Every Coil

Before a single pound of coil is rerolled or slit to spec, your material must be made. That happens at a melt mill and it’s where the lead time clock starts ticking.

At the melt mill, metal is produced in batches called “heats.” Each heat is a carefully controlled chemical recipe that’s melted in a large furnace. Typically, upwards of tens of thousands of pounds of a single alloy are melted at a time.

For common grades like 300 and 400 series stainless steels, heats are scheduled regularly, and availability is more predictable. But for specialty alloys, like some nickel-based or titanium grades, you might be waiting for the next heat to be booked, produced, and processed. That can add 8 to 20 weeks or more before rerolling or finishing even begins.

Rolling & Capacity Constraints

How the Melt Mill Schedule Affects You

Once a heat is produced, the material still needs to go through a series of rolling, annealing, and finishing processes before it becomes usable coil.

The problem? Melt mill schedules are optimized for efficiency, not urgency.

That means:

-

Changeovers are costly. Melt mills prefer to group similar alloys and gauges together to minimize downtime between runs.

-

Capacity is finite. If the mill is at capacity, new jobs go to the back of the line, even if the alloy is already available.

-

Specialty alloys take longer. Some materials require slower processing speeds or additional steps, like intermediate anneals or tighter thickness control. If markets that require these alloys are busy, capacity constraints become a factor.

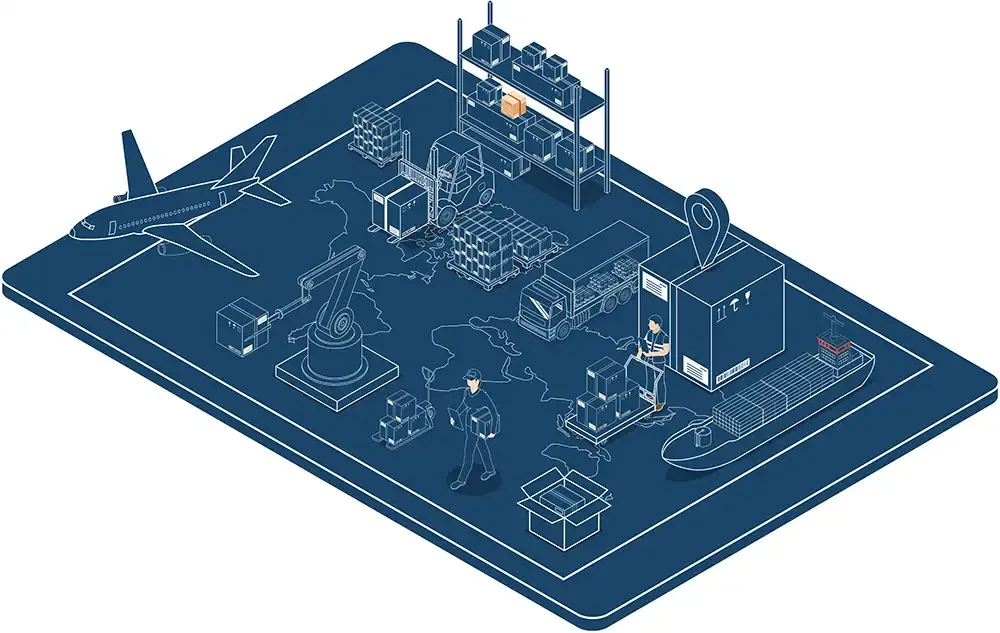

Regional & Global Sourcing: How Location Shapes Lead Time

Once the melt mill produces the coil, it must travel to your service center or re-roll partner. And whether the material was melted domestically or overseas has a direct impact on lead times and alloy availability.

Regional supply often reduces logistics time, offers faster troubleshooting, and ensures compliance with regulations. Global supply, meanwhile, can open access to specialty alloys or provide alternatives when domestic capacity is constrained.

Larger conditions, such as tariffs, shipping delays, or sudden demand spikes, also play a major role in how long it takes for material to reach your service center or re-roll partner, and ultimately, your floor. Manufacturers who understand these dynamics are better positioned to anticipate delays and build more resilient schedules.

One way to address these challenges is through a hybrid approach. By blending regional partners for responsiveness with global sources for expanded options, you can adapt sourcing to the specific needs of your business.

Learn how Ulbrich supports partners with a dual sourcing strategy by checking out this blog post.

Stock vs. Custom: Why Not All Lead Times Are Created Equal

Most customers assume material is either “available” or “not,” but it’s more nuanced than that. Lead times vary greatly depending on how your order is fulfilled, and there are two broad scenarios:

-

Your coil can be supplied by a service center and only requires slitting, cut-to-length, or basic edge conditioning.

-

Your coil must be custom-made at a re-roll mill because it requires re-rolling, annealing, tailored material properties, and tight-tolerance finishing.

Stock Material from a Service Center

Service centers maintain inventory of common alloys, gauges, and tempers that can be processed and shipped quickly. By drawing from stock, manufacturers can avoid the extended lead times associated with new production runs.

These facilities also provide value-added services such as slitting, cut-to-length, and edge conditioning, making coils application-ready without requiring a custom re-roll mill order. Service center products are best when efficiency, availability, and cost-effectiveness are the priority.

Custom Material from a Re-Roll Mill

Re-roll mills specialize in tailoring coil to exact specifications. Because each order must be scheduled, rolled, annealed, and carefully inspected, custom work inherently carries longer lead times than service center material.

Whether you need a specific temper or very tight mechanical and gauge tolerances, re-roll mills ensure consistent performance and engineered properties that may not be achievable through service center processing alone.

How Ulbrich Helps: A Smarter Supply Model

At Ulbrich, we’re solving production problems before they happen. Here’s how we reduce lead time pain:

-

Stocking Common Alloys: We maintain strategic inventory of high-volume stainless steel grades and special metals.

-

Reroll Flexibility: Our in-house reroll capabilities allow us to fine-tune temper, edge, and thickness quickly.

-

Smaller MOQs: You don’t need 20,000 lbs to get material moving. Our model supports low-quantity, high-precision orders.

-

Forecasting Partnerships: We’ll work with your team to pre-book materials and secure production windows, reducing lead time and risk.

-

Problem-Solving Engineers: Our metallurgists can recommend drop-in alloy alternatives that are available faster, without compromising performance or integrity.

How to Speed Things Up

The best way to reduce lead time is to give us what we need to get started fast. Here’s what to include in your RFQ:

-

Alloy and Condition (e.g., 301 Half Hard, not just “301”)

-

Thickness and Width (with tolerances if critical)

-

Edge Condition (e.g., deburred, round, square, custom)

-

Temper or Mechanical Property Targets (if applicable)

-

Certification Needs (AMS, DFARS, RoHS, REACH)

-

Application Details (so we can recommend alternatives if needed)

-

Required Quantity and Timeline (even a ballpark helps us advise)

Get the Right Material Faster by Picking the Right Partner

In a perfect world, your coil would always be ready when you are. But in reality, success depends on understanding the full upstream journey of your metal. From melting and rolling to stocking and finishing, each step impacts when your material shows up.

At Ulbrich, we help you navigate that complexity. Because getting great material eventually isn’t enough. You need the right coil at the right time. Contact us today to get started!