Understanding Camber in Rolled Strip Coil: A Guide for Precision Manufacturers

In some applications, slight imperfections might go unnoticed.

But those aren’t the kinds of applications Ulbrich supplies.

In precision manufacturing, even the smallest deviation can lead to issues. Strip coil that’s just slightly out of tolerance can disrupt production or result in parts that don’t meet spec. All of which create costly delays, rework, and lost efficiency.

One of the most common culprits behind these issues is camber, a subtle but serious coil defect that can wreak havoc on your production line.

In this article, we’ll break down what camber is, how it’s introduced during the rolling process, how to distinguish it from similar defects like coil set, and how Ulbrich helps ensure the strip you receive runs clean, flat, and true.

How Camber Affects Rolled Strip Coil

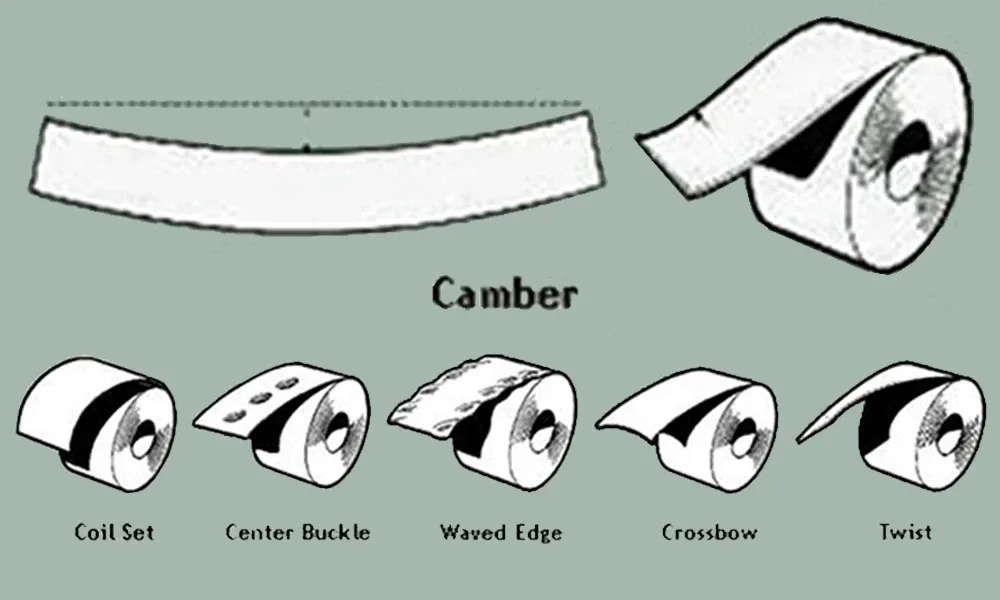

In an ideal world, rolled strip metal would be perfectly flat, with uniform thickness and straight, parallel edges. But in the real world, some degree of deviation is inevitable. When one edge of the strip runs longer than the other, causing the material to curve laterally rather than lie straight, the result is camber.

If the camber falls within an acceptable tolerance range, it usually won’t affect downstream processing. But if it exceeds spec, it can cause the strip to walk, wander, or bind which can lead downstream processing issues.

How Camber Is Introduced During Rolling

To visualize how camber forms, think of rolling dough with a pin. If you apply uneven pressure or your rolling pin isn’t straight, the dough won’t come out flat—it will curve. Metal behaves the same way, though with much higher forces.

There are several ways camber can develop during processing:

Uneven Pressure or Misaligned Rolls

When these issues occur during cold rolling, it can cause one edge of the strip to elongate more than the other.

Roll Deflection

When the force required to reduce thickness causes the work rolls to bend, it introduces a curve.

Slitting Process Variables

Slitting the coil into narrower widths can also introduce camber, especially if the slitter knives are misaligned or worn.

Once introduced, camber appears as a concave and convex side along the length of the strip. It’s typically measured by laying a straightedge along the concave edge and noting the deviation from center.

Camber vs. Coil Set: What’s the Difference?

Camber is often confused with another defect called coil set, especially in thin materials where the effects can look similar. But they are fundamentally different:

- Camber is an edge-to-edge curvature across the width of the strip.

- Coil set is a surface-to-surface curvature along the length of the strip, typically resulting from the coil memory after being tightly wound.

Here’s a quick way to picture the difference:

- If you bend a strip with camber into a ring, the ends meet cleanly, forming a near-perfect circle.

- If you bend a strip with coil set, one surface is longer than the other, leaving a gap or notch when formed into a circle.

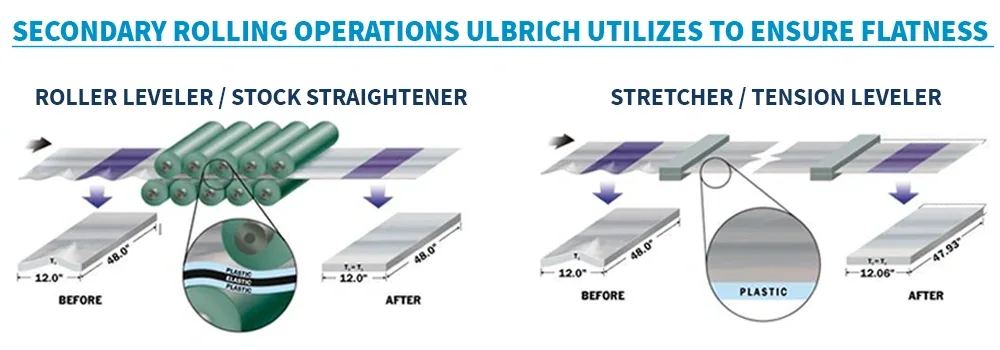

Correcting coil set usually involves flattening the strip while adjusting tension to compress the longer side or elongate the shorter one.

Other Coil Shape Defects to Know

Beyond camber and coil set, several other shape-related defects can occur during rolling or slitting. These include:

Center Buckle

When the center of the strip is longer than the edges, causing a wavy pattern down the middle.

Quarter Buckle

A wavy distortion between the edge and center, indicating elongation in the quarter-width zones.

Edge Wave

The inverse of center buckle; the edges are longer than the center, creating undulations along the edge.

Crossbow

Like coil set, but across the width of the strip rather than the length.

Twist

A torsional defect where one end of the strip rotates relative to the other, creating a helical shape.

Why Ulbrich’s Rolling Capabilities Matter

At Ulbrich, we specialize in producing precision strip coil that meets the tightest mechanical and shape tolerances. Our advanced rolling equipment and expert metallurgists work together to minimize camber and eliminate coil shape defects—ensuring your material performs as expected, every time.

For manufacturers in stamping, deep drawing, or any application requiring tight flatness and shape control, partnering with a precision re-roller like Ulbrich means fewer headaches, higher yields, and better product performance.

Have Questions About Camber or Coil Shape?

Connect with one of our metallurgists or product experts to review your application and ensure you’re procuring the optimal material.