Ribbon vs. Oscillate Wound Coil

When procuring specialty strip coil, customers must decide whether they want their material packaged as ribbon or oscillate wound.

Ribbon wound slit coil is the more traditional method and meets the needs of many manufacturers. However, oscillate wound coil offers clear advantages for some customers and should be strongly considered.

Learn the difference between oscillate and ribbon wound coil to decide which is best for your needs.

Ribbon Wound Coil

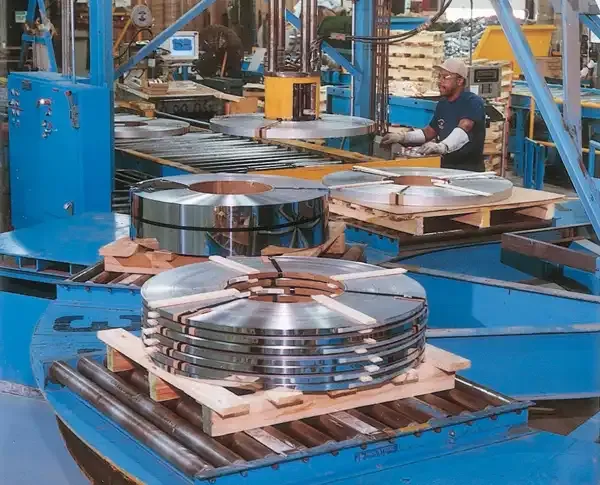

On a ribbon wound coil, also known as pancake slit coil, a single strip of metal is wound in a single row so that the edges are flush. This creates a comparatively thinner coil.

The easiest way to describe ribbon wound coil is that it looks like a large roll of Scotch gift-wrapping tape. Ribbon wound coils are often called pancake coils because of their flat packaging.

This is the most common method of winding steel strip.

Oscillate Wound Coil

To create oscillate, or traverse, wound coil, several pancake coils are first welded together.

After the strip metal goes through the edging process, the slit coil is wound onto the bundle so that each wrap winds alongside the previous wrap. This is just like how a garden hose or sewing thread is traverse wound horizontally across a spool.

When done correctly, the winding looks like a solid, perfectly aligned wire coil. The width of the finished oscillated coil is referred to as the face. Oscillation is typically done on finished widths of two inches or less.

With oscillate wound coil, several ribbon coils become one long, continuous strip (think up to 10 times longer than a single pancake coil). Welds are marked so customers can easily identify them during their own manufacturing processes.

Oscillating, particularly after being run through an edging process, assures a camber-free, tightly wound coil.

Reasons for Using Oscillate Wound Coil vs. Ribbon Wound Coil

Traditional ribbon wound coils may be the most used, but they are not without their disadvantages. One common issue is the amount of floor space needed for pancake coil, which is especially true if you have large volume requirements.

With an oscillated wound coil, more slit coil can take up the same amount of space occupied by pancake coils.

There are several other benefits of oscillated coil. For one, because oscillation creates finished coil with a run length up to 10 times longer, it can save time spent previously switching pancake coil — particularly if you’re working with large quantities.

This longer total continuous length for each metal strip can dramatically increase productivity. In fact, when using oscillated coils in a stamping operation, loading times can be reduced by up to 100% because you’re getting that much more footage for each coil.

Additionally, if the slit coil is thin or soft, oscillate wound coil can help protect the surface or edge conditioning. Oscillate wound coil is secured by high-tensile steel strapping, keeping coils secured in place on skids until it’s unloaded.

To demonstrate the benefits of oscillate wound coil, here’s an example of a real-life scenario.

Assume a company consumes 40,000 lbs. a month of narrow-width slit steel. To meet that demand, you would need up to 200 pancake coils. With oscillated coil, the number of coils can be reduced all the way down to 20. This reduces coil feed time by 180 coils, freeing production time and reducing waste, scrap, and manpower.

Consider the savings in both coil feed time and labor!

To summarize, oscillate coil offers:

- Fewer Changeovers

- Longer Run Times

- Reduced Startup Times

- Reduced Scrap

- Increased Savings

- Surface and Edge Protection

Choosing the Right Wound Coil

Ulbrich wants to help you choose the right wound coil for your precision strip metal. Although ribbon-wound coils are more common, our oscillate winding and technical capabilities offer unique savings and value to our customers.

Contact us today so that we can create a custom quote for your unique needs!