When Spec Isn’t Enough: How Coil Engineering Unlocks Press Performance

Stamping operations across industries, from automotive safety components to medical devices and consumer electronics, depend on presses running at full capability. Companies invest heavily in high-speed equipment and precision tooling with the expectation that production will be smooth, efficient, and predictable.

Yet many manufacturers discover that their equipment is not reaching its designed performance. Stroke speeds are dialed back. Operators make constant adjustments. Scrap rates creep upward. In many cases, the press itself is not the limiting factor. The real issue may be the coil feeding into it.

The Gap Between “Spec” and Real Performance

Meeting ASTM or customer specifications is only the starting point. Thickness, tensile strength, elongation, and grain size may all be within tolerance, but stamping presses do not run on numbers alone. They run on consistency.

In a progressive die, even slight shifts in yield strength can redistribute loads across stations. One punch absorbs more force, while another introduces wrinkles or uneven draw. Operators respond by slowing stroke rates, and the equipment quickly falls short of its designed performance.

The result is a common frustration: coil that technically meets spec, but undermines efficiency because it was not engineered for the process.

Why Process-Compatible Coil Matters

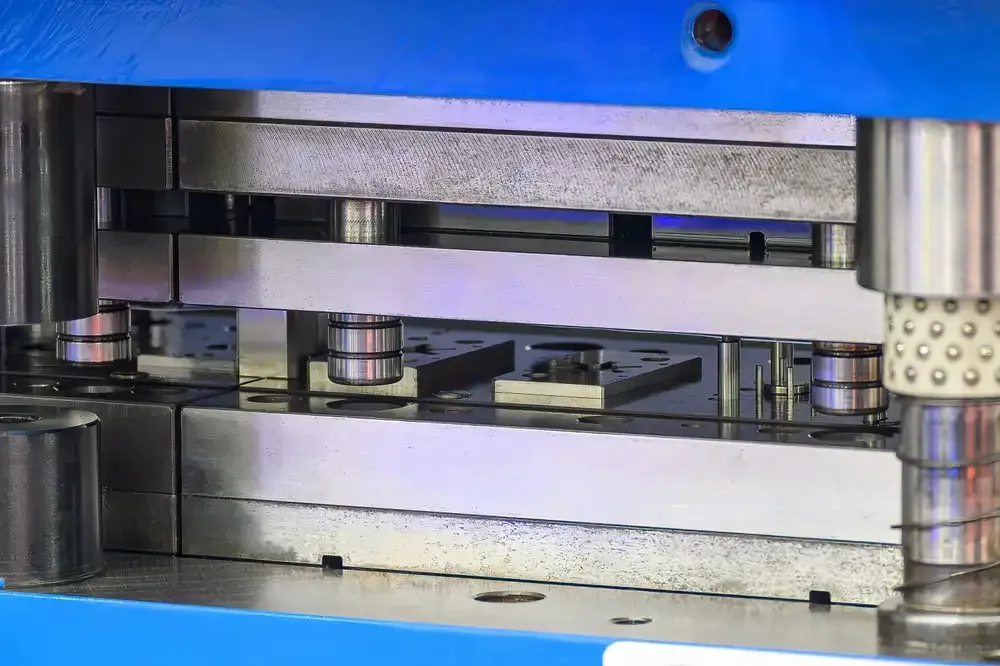

A stamping press is not just a machine; it is a finely tuned system. Tooling, feed mechanisms, lubrication, and part geometry all rely on predictable strip behavior. When coil properties vary, the harmony breaks down.

Ulbrich takes a different approach. Instead of stopping at spec, we engineer coil for compatibility with your application. This means:

- Tighter gauge control

- Mechanical property windows aligned with your manufacturing process and end application.

- Grain sizes aligned to your drawing requirements.

- Edge and surface preparation tailored to your specific requirements.

By aligning coil properties with press conditions, the system operates as intended and performance once hidden in the press becomes accessible.

The Payoff on the Plant Floor

When coil variability is reduced, the improvements extend across the operation:

- Higher throughput as presses can safely run closer to their designed stroke speeds

- Tooling longevity with less overload, galling, and premature wear

- Operator efficiency since there is less firefighting and more focus on production

- Scrap reduction with fewer first-article reworks and mid-run rejects

- Planning confidence as cycle times stabilize and schedules become more reliable

Manufacturers that switch to engineered coil often see noticeable gains in performance. Stroke rates increase when variability is minimized, and scrap drops when springback becomes more predictable. These improvements come not from changing dies or presses, but from using coil tailored to the process.

Stop Compensating, Start Performing

Manufacturers do not invest in high-end stamping systems to run them at half capacity. If presses are consistently running slower or requiring constant adjustments, the problem may not be with the equipment. The issue may be with the coil.

By treating coil as an engineered component of the stamping system, manufacturers unlock more capability, efficiency, and consistency. That is the Ulbrich difference: precision strip designed not just to meet spec, but to perform in your process.