The True Cost of Coil Variability in Stamping Operations

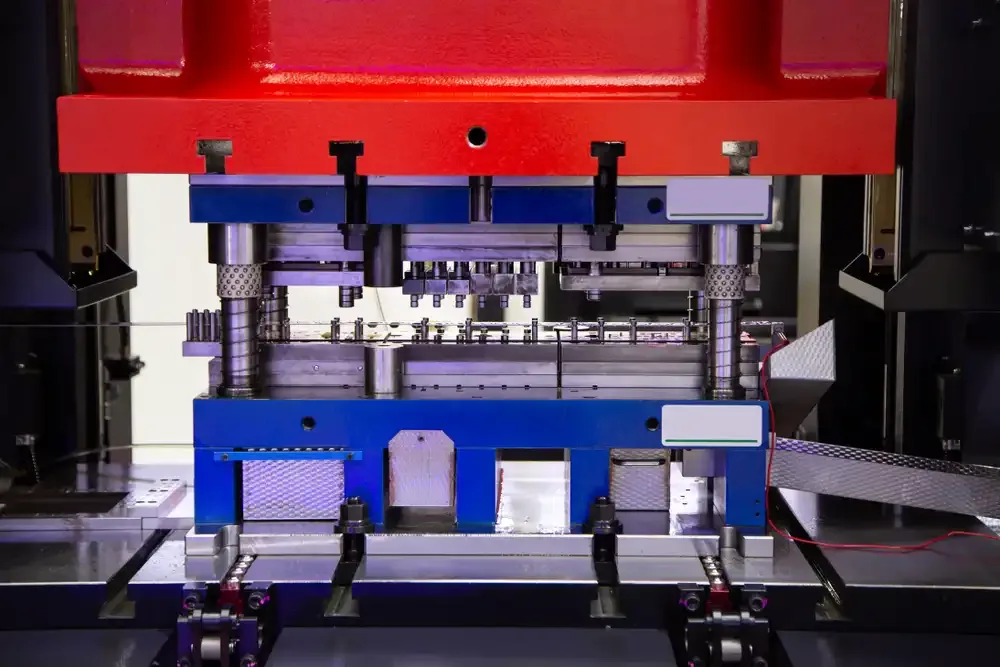

In competitive manufacturing environments, efficiency is not optional. Automotive suppliers face cost reduction demands, aerospace manufacturers must meet strict quality controls, and consumer goods producers are racing to deliver high volumes on time. In every case, the stamping press sets the rhythm of production.

When that rhythm is disrupted by coil variability, the costs are significant. Lost uptime, higher scrap, shorter tooling life, and missed delivery commitments all follow. Coil variability does not just slow production. It undermines control.

How Variability Creeps In

Most coil on the market is produced to broad industry standards. These certifications ensure baseline compliance, but they do not guarantee uniform behavior across an entire lot or shipment. Common issues include:

- Gauge drift

- Grain inconsistency

- Residual stresses

- Mechanical property shifts

On the plant floor, these small changes create major problems. Operators compensate by slowing feeds, recalibrating dies, or even halting production. Over time, variability compounds into missed cycle time, increased maintenance, and scrapped parts that never should have been made.

Precision Coil Built for Consistency

To avoid these disruptions, coil must be engineered for consistency rather than just compliance. Ulbrich’s rerolling operations are designed to eliminate variability at the source.

By working directly with manufacturers, Ulbrich tailors coil properties to the process:

- Gauge control

- Yield and tensile properties locked to application-specific ranges

- Flatness correction built in during rolling rather than adjusted afterward

- Grain sizes aligned to your drawing requirements.

- Surface finishes matched to lubrication and processing requirements

This approach ensures that every coil behaves consistently, run after run.

What Stable Coil Delivers

When coil variability is minimized, the improvements ripple across production:

- Setup efficiency since dies do not require constant recalibration

- Increased throughput with presses running at higher, stable speeds

- Tooling protection as even load distribution extends die life

- Scrap reduction with fewer defects driven by variability in springback or edge cracking

Manufacturers that adopt precision-engineered coil frequently report fewer disruptions, more predictable throughput, and more efficient use of press time. Instead of reacting to variability, teams can focus on production and planning with confidence.

Consistency is Control

Manufacturers cannot afford to spend valuable time compensating for coil variability. By sourcing precision strip that performs consistently from coil to coil, production teams move from firefighting to stable, efficient output.

At Ulbrich, coil is engineered as part of the process. The result is material that helps manufacturers maintain control, protect their investment in tooling, and achieve the efficiency their operations demand.