Metal Grains: The Hidden King of Metal Manufacturing Operations

At the center of every hated high school science class are the theories and laws surrounding atoms. Atoms make up our world and everything in it. They are the food we eat, the table we eat off, and the chair we sit in. We know that in a solid state of matter, atoms are unmoving and bond to other atoms, forming a shaped lattice. However, how the atom governs the properties of solid matter, such as mechanical strength and ductility, is a large part in why atoms are so important in the scientific community. In this article, we will look at how atoms govern properties in metals.

So, let's talk about metal atoms...

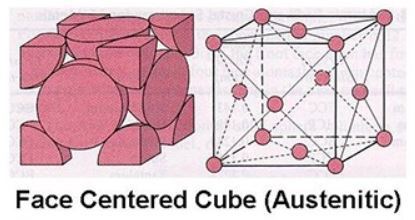

Atoms, when in solid matter, align to form a shape. While the electrons within the atom are orbiting, the atom itself is not moving and is linked to other atoms. In metal, these atoms align to form predetermined structure. This is known as a crystal structure. Depending on the phases and different atoms present, this crystal lattice can vary from alloy to alloy. In one of the most common alloys, 301 stainless steel, the austenitic stainless steel structure is formed through a face-center cubic crystal structure. This is also known as an FCC structure. To classify these structures, metallurgists use unit cells. Unit cells are diagrams of the crystalline structure drawn from the atoms that make up one of these crystals.

A face centered cubic structure is characterized by having four atoms surrounding one atom in the center of each face of the cube. This crystalline structure will repeat throughout the bulk of the material and makes up what we see as metal. Obviously, this repeating structure occurs an immeasurable number of times throughout the material. This repeating structure, when looked at macroscopically, is what makes up a grain.

What are grains and grain boundaries?

A grain is a collection of many repeating crystalline structures all oriented in the same direction. Grains can vary in length and width, depending on how long the repeating crystals go on for. When two grains oriented in different directions meet, a grain boundary is formed. As seen in the image below, this grain boundary phenomenon is due to varying orientations in crystal structures. The many grains and grain boundaries are what make up the entirety of the material. These grains can vary in size and shape, direction and orientation.

A dislocation occurs where there is an irregularity in the crystalline structure of a grain which allows atoms to slide over each other. Grain boundaries act as a barrier to that dislocation. A small grain size increases the number of these grain boundaries that must give way before movement can occur. This small grain size, having more grain boundaries, results in a stronger material. As a precision reroll mill, Ulbrich's entire process revolves around understanding and manipulating grain and grain structures such as this. The more control we have in this process, the tighter our mechanical tolerances can be, as well as several other improvements.

How does work hardening affect grain?

In order to change the structure of metal on a microscopic level, a large amount of energy is needed. This energy, in our case, comes from two sources; mechanical deformation and heat treatment. Mechanical deformation, or cold rolling at room temperature, is the heart of Ulbrich. At first glance it may appear to some as though precision rerolling with a rolling mill is only good for producing thinner material. However, the improvement in mechanical properties, especially the yield strength through strain hardening in a rolling mill makes this type of grain refinement attractive. Tempering material through rolling alters grains, offering high mechanical strength material with little drawback. At the core of the rolling process is manipulation of grains.

Grain refinement through annealing

The other method in manipulation of grain structure is through a heat treatment known as annealing. Heat is a much more cut and dry form of energy, and its process in changing grains can be explained very simply. As the metal is annealed, the grains begin to gain more and more energy. The grains will change once they have been given enough energy at a specific temperature, known as the recrystallization temperature. This energy causes the grains to nucleate outward. As grain growth occurs, they being to "eat" each other, with the larger grains incorporating the smaller grains into themselves. What you are left with is a microstructure of large grains, ready to be tempered again or used for various applications. Increases in temperature above the recrystallization temperature can result in bigger grains but can lead to a total wipe in grain structure if done for too long or at too high a temperature.

How do grain size and structure impact your manufacturing operations?

Metal manufacturing revolves so heavily around grains, grain size, and grain structure manipulation because this process is key to achieving good product. By manipulating grains scientifically and precisely, a manufacturer can not only create an end-product within specification, but also do so with much more ease and accuracy. By not only specifying mechanical properties, but grain size as well, post-processing steps like drawing, stamping, coining, and machining all become much more consistent with lower scrap rates. Grains directly affect every post processing application greatly. A grain structure with too much preferential direction can lead to difficulties in drawing. An under-annealed grain structure can cause issues in forming. But a customer working with consistent and accurate grain structures every lot means less time tooling for every individual material shipment and more time running.

By purchasing a better grade of material where grain size is specified, you could save many hours of production time and cost. That's why Ulbrich has a team metallurgists on staff to help our customers identify the ideal grain and material characteristics required for their manufacturing operations, specifications, and ultimately, application. If you have questions about grain, or any other alloy characteristics, we'd be happy to help! Contact a specialist today to learn about how you can save time and money by purchasing the ideal material for your needs!